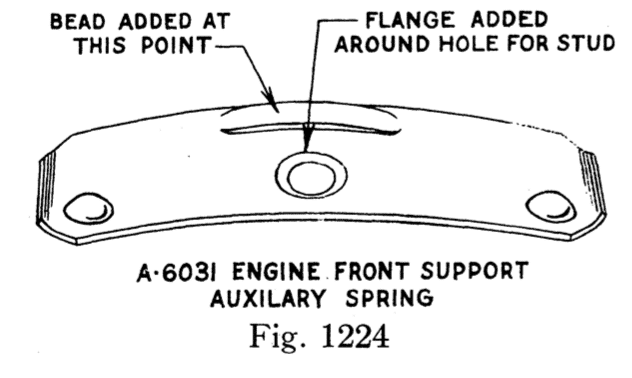

SUPPORT SPRING STRENGTHENED

To still further increase the strength of the A-6031 engine front support auxiliary spring, a flange has been added around the hole for the engine support stud and a bead added next to the hole. (See Fig. 1224.) This type of construction materially increases the strength of this part.