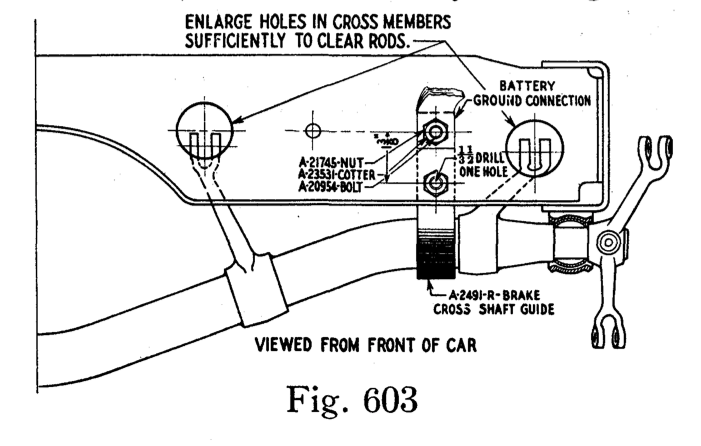

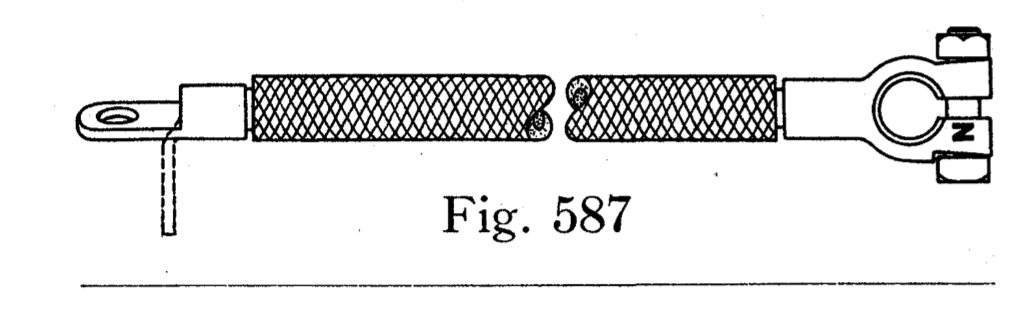

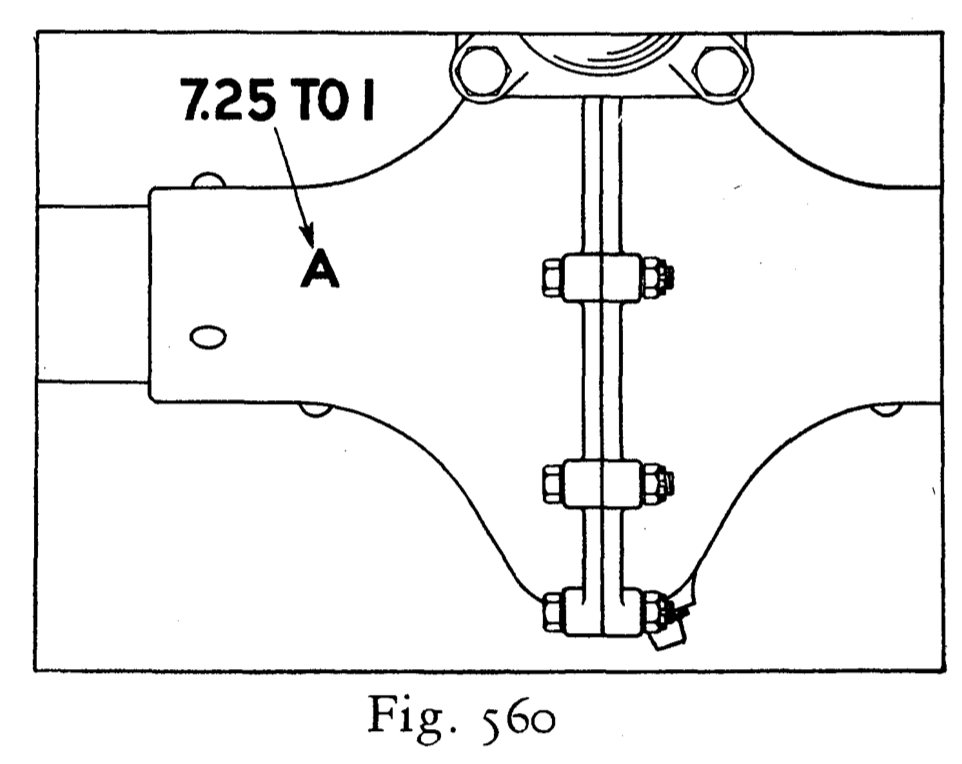

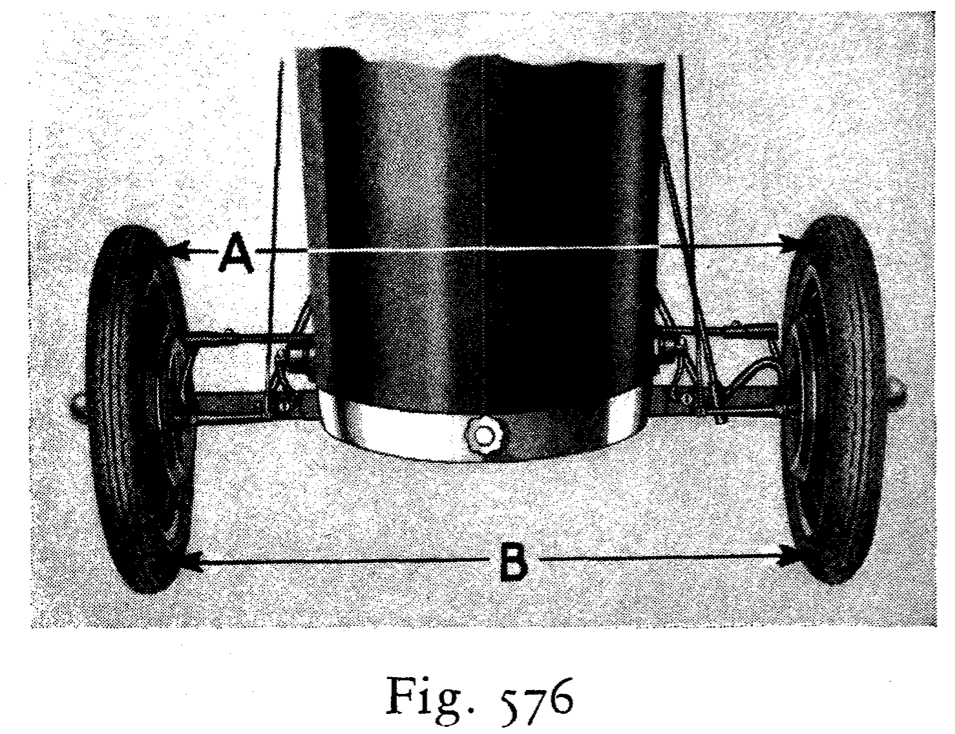

New Solid Brake Cross Shaft

New Solid Brake Cross Shaft A new service brake cross shaft assembly has been designed and is now standard on all cars and trucks. The new shaft replaces the old style cross shaft and equalizer assembly, as the old assembly is obsolete and will not be carried for service. The new shaft is unusually efficient, …